What is Polyethylene Corrugated Duct ( PECD): PECD are used for the construction of underground duct system for fiber optic and copper cables in the telecommunication’s long distance, junction, primary and secondary networks. PECD provide a single and continuous duct laying operation from one point to another, e.g., manhole to manhole, without cut. It can be laid directly into fiber optic trench at standard depths even without sand bedding . Concrete encasement is normally not required.

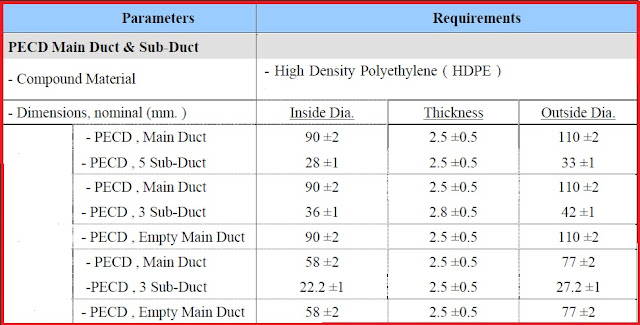

PECD main duct and sub-duct designed mentioned in below table-

Typical service conditions of PECD for a minimum period of fifty (50) years without detriment to the operation and maintenance characteristics of the product. PECD and its accessories shall be designed, manufactured and packaged so that its physical or operation and maintenance characteristics shall not degrade when exposed to the environmental conditions. PEDC is capable to tolerate the environmental conditions ambient air temperature variations from -10° to +55°C. In addition it can tolerate direct solar radiation temperature up to the +70°C in hot areas.

|

| Use of PECD in Telecommunication Network |

Use of Polyethylene Corrugated Duct ( PECD)

The PECD shall be compatible with the latest installation standards and operation and maintenance practices for the telecommunication’s duct system. PEDC also built-in sub-ducts. It shall be flexible and easy to install. The PECD shall be free of blisters, shrink holes and inhomogeneities, which might impair the performance of the ducts in service.

The PECD shall be acceptably round. It shall be supplied with its ends cut cleanly at right angles to the axis of the duct. The PECD and its accessories shall be unaffected by all kinds of corrosive liquids and other compounds which exist in the underground system. PECD are supplied in various size, for details check the below table.

|

| PEDC size |

|

| Parameter of PECD main and sub-duct |

Main duct wall design: Inner and outer walls shall be corrugated with average pitch dimension of 25.4 ±1 mm for 110 mm PECD and 23.5 ±0.5 mm for 77 mm PECD .The corrugation shall either be helical or annular (ring).Outer and inner walls shall be plain and smooth.

Fusion of main duct and Sub-ducts: All contact surfaces between main duct and built-in sub-ducts shall fuse together during extrusion process. This fusion shall prevent movement or twisting of sub-ducts inside the main PECD (in finished products).

Color: The main duct shall have color of bright orange.The sub-ducts shall have the same color as that of the main duct, except that one sub-duct should always have black color separate from the other sub-ducts.

Connectors: The connector shall connect and secure the PECD at one end, and connect to M/H duct entry hole , at its other end.All mating surfaces between connector and PECD and duct entry holes, shall be watertight. Solvent cement used for jointing pipes, may be applied.

The coupling shall be equipped with 6 rows of rubber ‘O’ rings placed inside the coupling to provide watertight seal between two sub-ducts. The coupling shall be corrugated in shape with pitch dimension of 25.4 +1 mm for 110 mm PECD & 23.5 +0.5 mm. for 77 mm PECD.

The coupling shall provide mechanical protection and watertight seal between two connected PECD.The coupling and main PECD shall be compatible with the standard solvent cement used for jointing pipes.

PECD End Cap: To serve as End Cap for PECD, so as to prevent entry of dust and particles during transportation from factory to work site , during storage at site warehouse and after installation of duct at the work site -prior to installation of cable in the duct .

The end cap shall be corrugated in shape with pitch dimension of 25.4 + 1 mm for 110 mm PECD and 23.5 +0.5 mm for 77 mm PECD.The end cap shall provide protection to the ends of the PECD and act as seal against dust / water. The end cap and main PECD shall be compatible with the standard solvent cement used for joining pipes.

PECD supply lengths: Other lengths may be supplied, but usually supply lengths are- Supply Length 300 Mtr with Reel Size (meter) 2.3 Dia. x 1.7 Width and 600 , 1200 Mtr with 2.8 Dia. x 1.7 Width.

Each length of PECD shall be packaged in individual steel reels. The reels shall be absolutely sufficient to protect the PECD from damage during handling, storage and transportation. PECD accessories shall be sufficiently packaged in a carton box to be protected from damage during handling.

2 Comments

The information which you have provided is very good and essential for everyone. Keep sharing this kind of information. Thank you. used warehouse equipment

ReplyDelete1853EE0AC2

ReplyDeletehacker kiralama

hacker kirala

tütün dünyası

-

-