What to do before FTTH cable installation in duct? : A simple issue but very important on which we are going to talk that What to do before FTTH cable installation in duct and why? Under the supervision of some site engineers FTTH cable install incorrectly in the duct and then they try to hide it with the contractor.

Even during the final audit of FTTH project, some excuses are made to open that particular MH / HH and not being opened, in which the cable is not installed in the specified duct. When there is a fault in the future, then there is a lot of trouble and the FTTH maintenance team has to face problems.Do not make this kind of mistake, in this article today I am discussing the same subject.

During installation the cable shall be carefully inspected. Each case of damaged cable discovered before or during installation or by tests or observations after installation shall immediately be brought to the attention of the FTTH project supervisor.The damaged cable section shall be repaired or replaced promptly. Cable found faulty after being installed shall be replaced by new undamaged cable.

The transmission quality and characteristics of fiber optical cable are degraded when the cable is subjected to excessive pulling tensions, compressions or to small bending radii. Additionally, the number of fusion joints in a repeater section are designed to a minimum, to reduce transmission losses.

Cables in vertical shafts shall be secured according to the manufacturers recommendations and at not more than 200-cm intervals.All necessary precautions must be observed when pulling cables through conduits to ensure damage to the cables or conduit does not occur.

Branch cables which must cross from one side of the manhole to the other, shall be led preferably above the duct faces, or if necessary, below (for the bottom cables).

Even during the final audit of FTTH project, some excuses are made to open that particular MH / HH and not being opened, in which the cable is not installed in the specified duct. When there is a fault in the future, then there is a lot of trouble and the FTTH maintenance team has to face problems.Do not make this kind of mistake, in this article today I am discussing the same subject.

|

| FTTH Cable installation |

Duct, Sub-Duct, Mini Duct in FTTH Project

We all know that duct, sub-duct and mini-duct are used in FTTH project. Different number of ducts are used in different FTTH project according to the location and requirement. The important thing is that what should be completed before cable installation in these ducts.

All new ducts, sub ducts and mini ducts shall be rodded and cleaned before testing. A test mandrel with a main body of 200-mm length and 95 mm diameter, shall be pulled through each new 100-mm duct in the formation. If any obstruction is encountered, the duct must be cleaned again and, if necessary, repaired before it is tested again.

Bends of radius 2 m and less, which will not pass the reference mandrel, shall be proven with a ball mandrel of 95-mm diameter.

If pressure testing is to happen then pressure testing shall consist of pressurizing a duct to 25 kPa (0.25 kg/cm2), allowing the pressure to stabilize, after which the pressure shall remain within + 2 kPa (0.02 Kg/cm2) for 30 minutes.

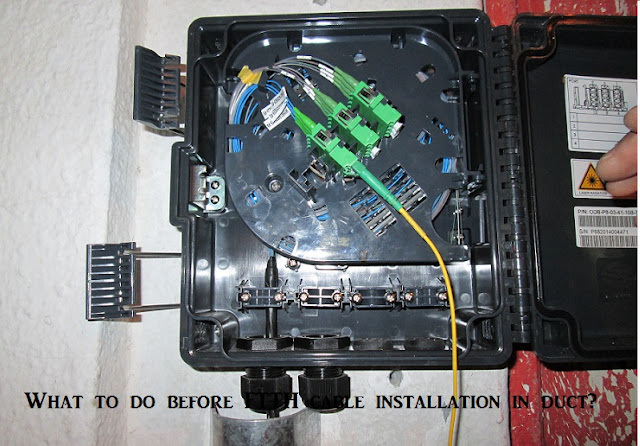

FTTH Cable Installation

Cable shall not be pulled along the ground,allow correct installation methods to be followed (roller, winches, tension gauges, lubricants, man power etc).During installation the cable shall be carefully inspected. Each case of damaged cable discovered before or during installation or by tests or observations after installation shall immediately be brought to the attention of the FTTH project supervisor.The damaged cable section shall be repaired or replaced promptly. Cable found faulty after being installed shall be replaced by new undamaged cable.

Cable cores shall be protected at all times. When the cable sheath is opened, the cable core shall be protected to prevent the ingress of moisture and deleterious material.

For pressurized cables, drum lengths shall be pressurized and shall be pressure checked upon arrival at the work site. lf the pressure has fallen by 10% of that indicated by the last pressure test data, within a six month period (pressure fall shall be reduced pro-data for time periods less than six months e.g. 3 months, 5% fall), the drum shall be returned to the stores for examination. Pressure shall also be checked after cables have been installed.

FTTH Cable in Duct

The transmission quality and characteristics of fiber optical cable are degraded when the cable is subjected to excessive pulling tensions, compressions or to small bending radii. Additionally, the number of fusion joints in a repeater section are designed to a minimum, to reduce transmission losses.

The following should be observed

➤Pulling tension must not exceed 2.0 kN for duct cables and 1.0 kN for direct buried cables.

➤The minimum dynamic bending radius for moving cable is 20 times the outside diameter of the cable.

➤The minimum static bend for fixed cable is 10 times the outside diameter of the cable.

➤If the cable is laid out on the ground, no traffic of any form can be allowed to run over it.

The cable should not be cut at any point that is not specified by the FTTH project Engineer. The FTTH project Supervisor/Engineer should be consulted regarding any circumstances developing which may require additional cable cuts and consequent joints.

Cable tension shall be monitored continuously during installation. The absolute force applied to the cable during the pulling shall be monitored continuously.

Generally, where cable is installed in sub-ducts, care shall be taken to ensure that any pulling lubricants being used do not "pack" or otherwise form obstructions to the cabling progress. The use of lubricants is to be carefully controlled by the FTTH Project Supervisor.

All Fiber Optical cables to be hauled in existing or new conduits shall be placed in sub-ducts.Fiber Optical cables shall be installed in the upper layer of a duct route whenever possible.

All ducts shall be cleaned and mandrel tested before cables are installed.Any potentially damaging situations determined during the mandrelling operations shall be examined before proceeding with any installation.

Cables except fiber optic cables shall always be allocated so as not to obstruct future placing of other cables, i.e. placing shall always start at the bottom row of the duct assembly, placing the cables row after row, unless otherwise specified by the FTTH Engineer.

Ensure that a swivel connector shall be used to attach the grip to the pulling rope. FTTH Cable shall be pulled using cable protection guides and every effort shall be made to reduce the possibility of any damage to the FTTH cable.

Two or more primary or secondary cables may be pulled into the same duct providing the combined cable diameters do not exceed 90% of the duct diameter and the length of the cable section will allow easy placing.

FTTH Cables being pulled into duct shall be lubricated with an approved lubricant as required. Suitable precautions must be taken to ensure the maximum allowed pulling force, according to the cable supplier's directions, is not exceeded.

When the cable has been secured in the manhole the duct shall be sealed with a suitable compound, which will allow the removal of the cable at a future date.

FTTH Internal Cabling

Indoor cables/wires may be installed in ducts, on raceways or attached directly to walls. Where possible, ducts and other installations into which cable can be conveniently installed, shall be chosen.Cables in vertical shafts shall be secured according to the manufacturers recommendations and at not more than 200-cm intervals.All necessary precautions must be observed when pulling cables through conduits to ensure damage to the cables or conduit does not occur.

How to Install a Joint Closure in MH/HH

The location of a joint enclosure in a manhole shall be specified by the FTTH project Engineer. In order to facilitate future cable re-arrangements "branch" cables joining a "main" cable, shall be looped at least halfway around the manhole, before entering the joint.Branch cables which must cross from one side of the manhole to the other, shall be led preferably above the duct faces, or if necessary, below (for the bottom cables).

4 Comments

Nice post, getting FULL Information at one place its really good,, !!! Planet most love music app mp3 juice get here thanks ....

ReplyDeleteNice post, getting FULL Information at one place its really good,, !!! World most Famous app to make life easier without any problems thanks ....

4BB3E3844C

ReplyDeletekiralık hacker

hacker kirala

tütün dünyası

hacker bulma

hacker kirala

953B77873A

ReplyDeleteSanal Seks

Telegram Show

Görüntülü Şov Whatsapp Numarası

D1DBEE16C1

ReplyDeleteBeğeni Satın Al

Sahte Takipçi

Takipçi Fiyatları